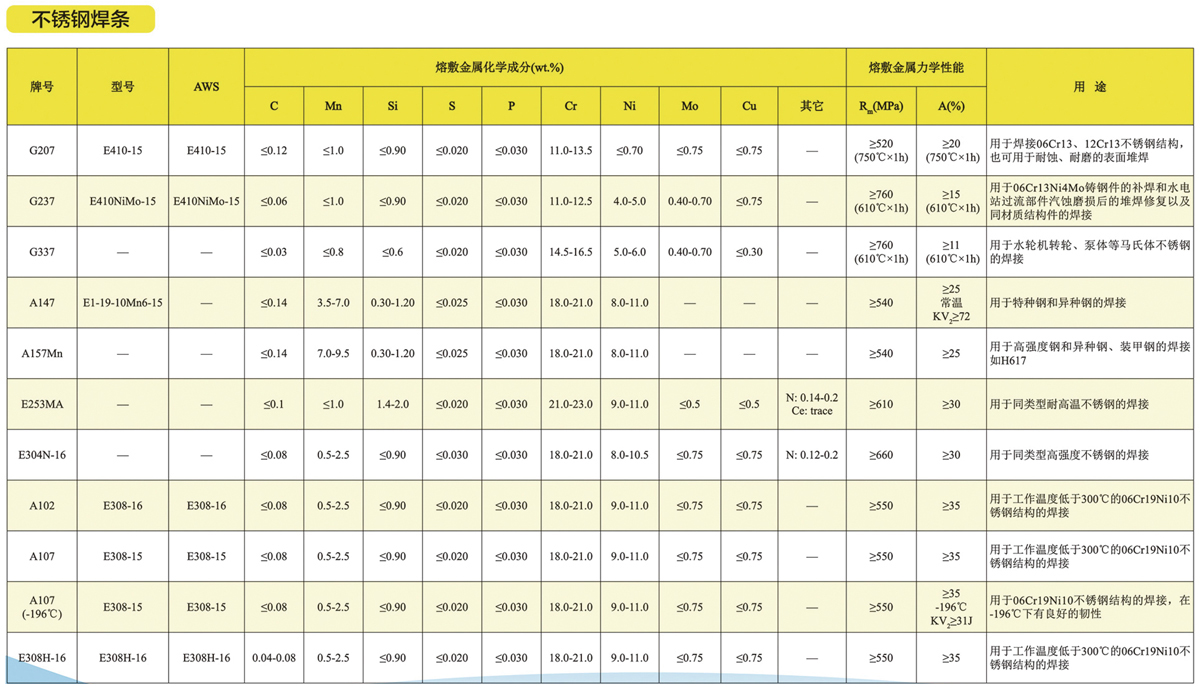

不锈钢焊条

不锈钢焊条

Stainless steel welding electrode

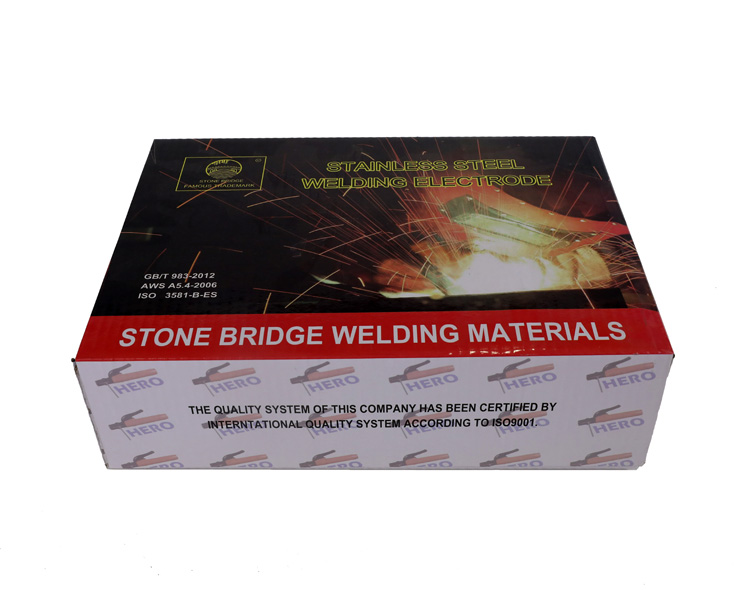

不锈钢焊条具有良好的力学性能及抗晶间腐蚀性能,操作性能极好,能进行全位置焊接。用于焊接工作温度低于300°C的耐腐蚀的0Cr19Ni9,0Cr19Ni11Ti不锈钢结构义及构义及堆焊不锈钢表面层。

Stainless steel welding electrode has good mechanical property,Roocyintervryctaline corrosion-resistance,excellent operating properties,suitable for all positions.used for welding 0Cr19Ni9,0Cr19Ni11Ti corrosion-resistant stainless stee steel structuresworking temperature is lower than 300 C,surfacing stainless steel welding electrode

| E308L-16 | E312-16 |

|

|

| E308-16 | E309-16 |

|

|

| E316-16 | E309L-16 |

|

|

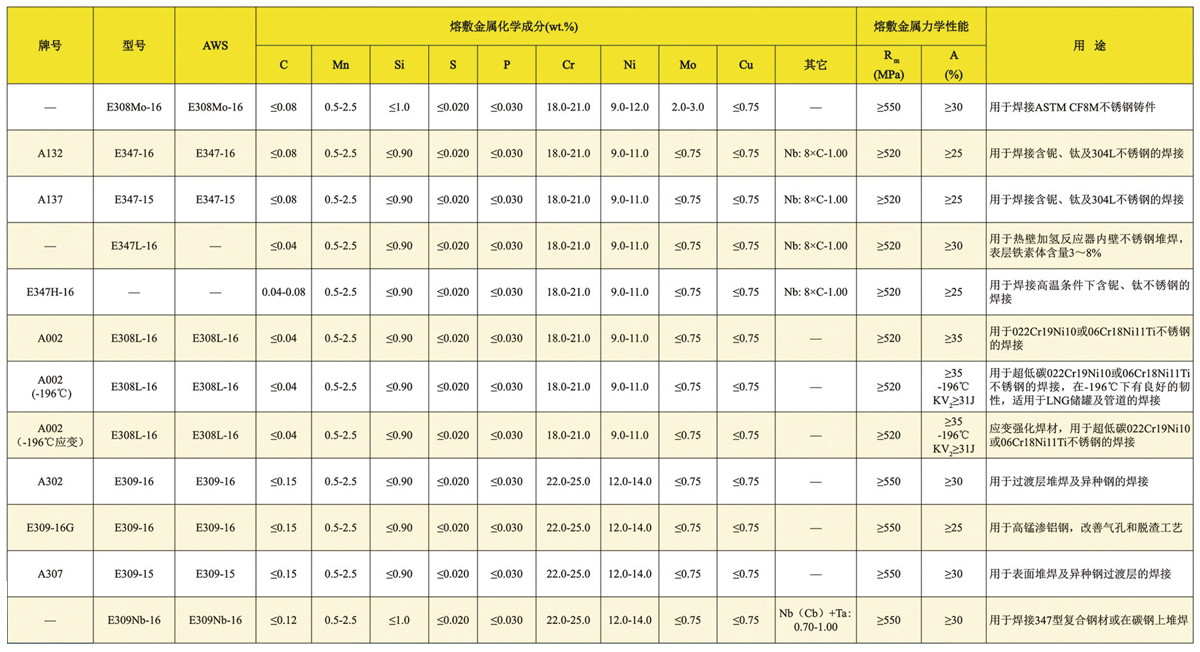

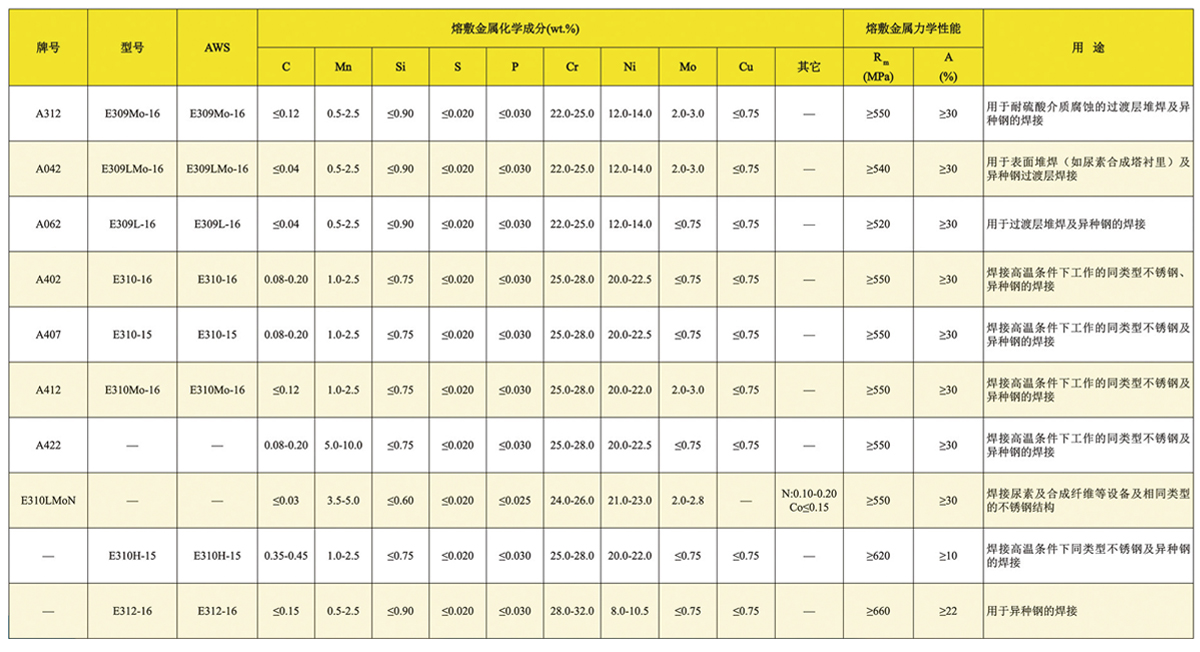

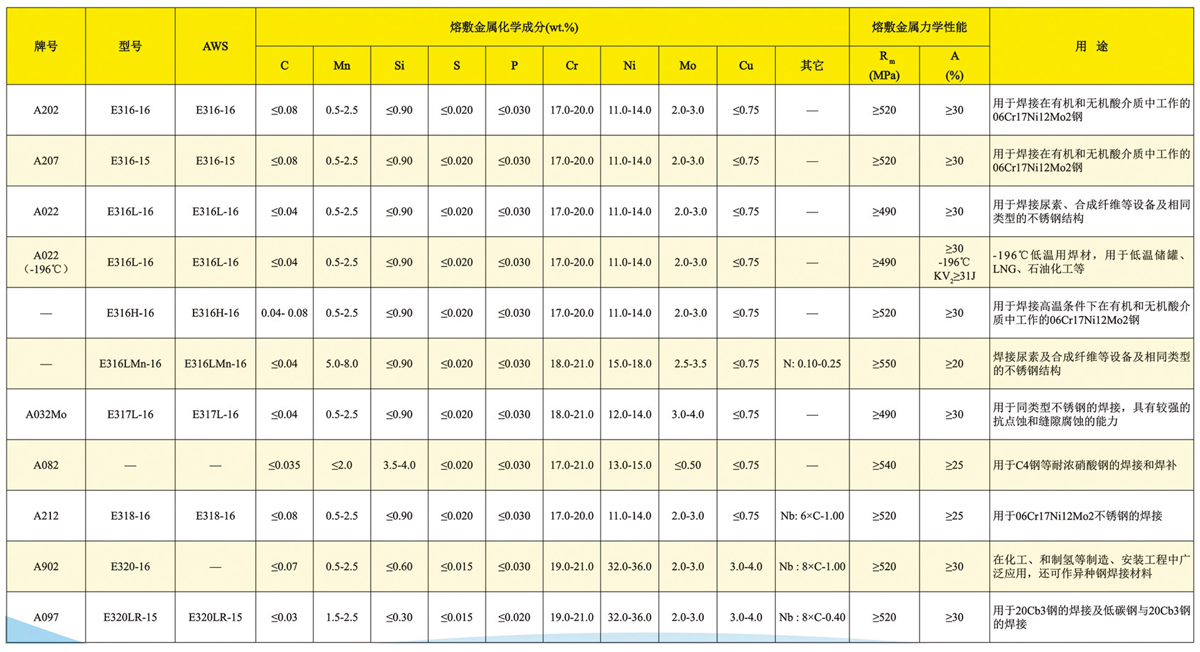

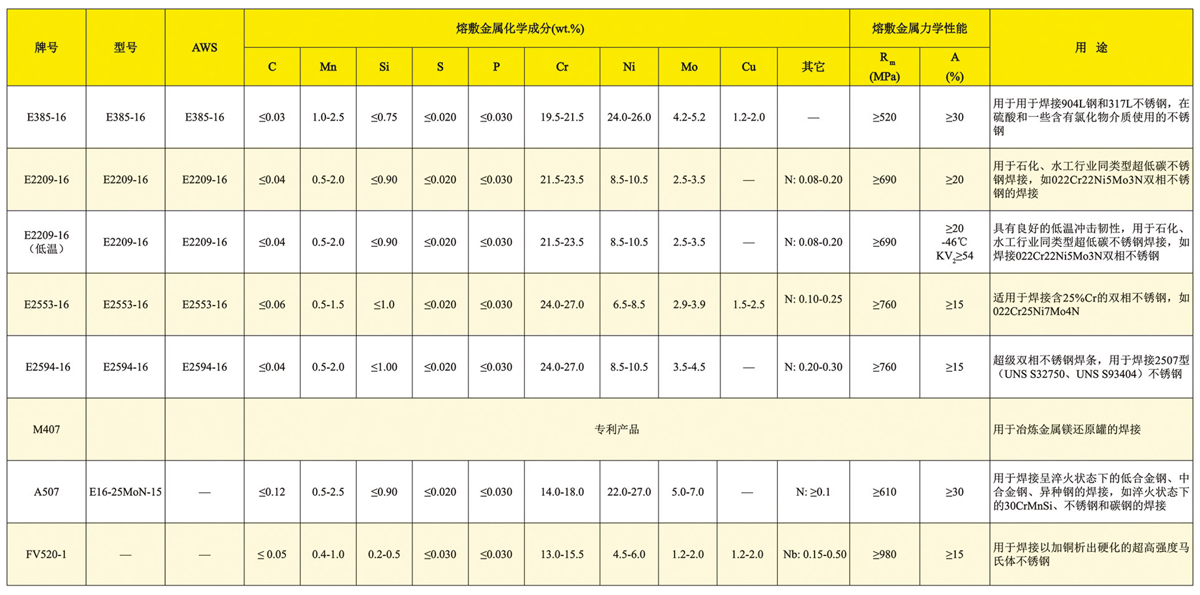

性能参数

performance parameter